Why is the Train Track Designed in the Shape of a Light Bulb?

As one of the main land transportation modes, railroad transportation plays an important role in our daily life. In the past, when science and technology were not yet developed, railroads were equated with the track routes on which trains ran, and steel wheel travel was also the traditional way for trains to run on the tracks. Nowadays, the term railroad transportation has covered non-steel wheel travel methods such as ropeways, maglev trains and cable cars, which are involved in everyone's daily travel.

With the advent of the "high speed rail era", rail grades have become more complex, with different categories of classification such as network grades, passenger and freight grades, and speed grades. On the whole, the national railway class I is lower than the high-speed railway class, and although the former includes some fast railroads, there are also many ordinary railroads.

Although, two trains that are running in the same direction will always run at a relatively safe distance, each train that is pulled by a locomotive has its own established route of travel. For example, in some places where the terrain is rather special, the shape of its tracks is like a light bulb.

What is a spreading line?

In essence, the so-called light bulb shape is actually one of the manifestation forms of the spreading line, which usually appears in some places with special geographical location. Its main purpose is to keep the train running in good condition on the railway line in this shape. Because, there is a maximum longitudinal slope value of the line of train operation, and when the natural longitudinal slope of the ground is greater than the value, it is necessary to slow down the longitudinal slope by reasonable spreading line settings, such as the light bulb line.

Designing different forms of spreading lines is the main means to mitigate longitudinal slope

In fact, the construction of the railroad will be greatly restricted by the terrain, when the technical staff in the design of the railroad line, it is necessary to start from the actual terrain, and the extension of the line has become the main means to mitigate the longitudinal slope, especially in the past when the technical conditions were still relatively low.

Additional reading:

Stainless Steel Sheets with Vibration Non-Directional: An Aesthetic Marvel

Customized Steel Bridge Guardrail: Ensuring Safety and Efficiency in Bridge Infrastructure

What the best ppi should be chosen for metal filtration

5 Tips on How to Maintain a Gazebo

Advantages of Color Coated Steel Coils

How Long Do Steel Rails Last?

How do I choose the right decorative wire mesh for my project?

Because, whether it is the traction conditions, or the difficulty of building large span bridges and long tunnels, this has led to overcome the elevation barrier only by means of line extension. Therefore, often those who need to train over the mountainous areas, is the common area of the spread line. The so-called "light bulb line" is actually a kind of circuitous spreading line when the length of the spreading line is large, also known as complex spreading line.

About the geometric position of the railroad track

The basic size, relative position and geometry of the track are the characteristic information contained in the track geometry, which is managed differently in dynamic and static states. As the name suggests, the former means the condition of the track when there is a train running on the track, which is mainly measured by means of a track inspection vehicle, while the latter means the condition when there is no train running, which can be measured by means of a track gauge or a relatively small track inspection vehicle.

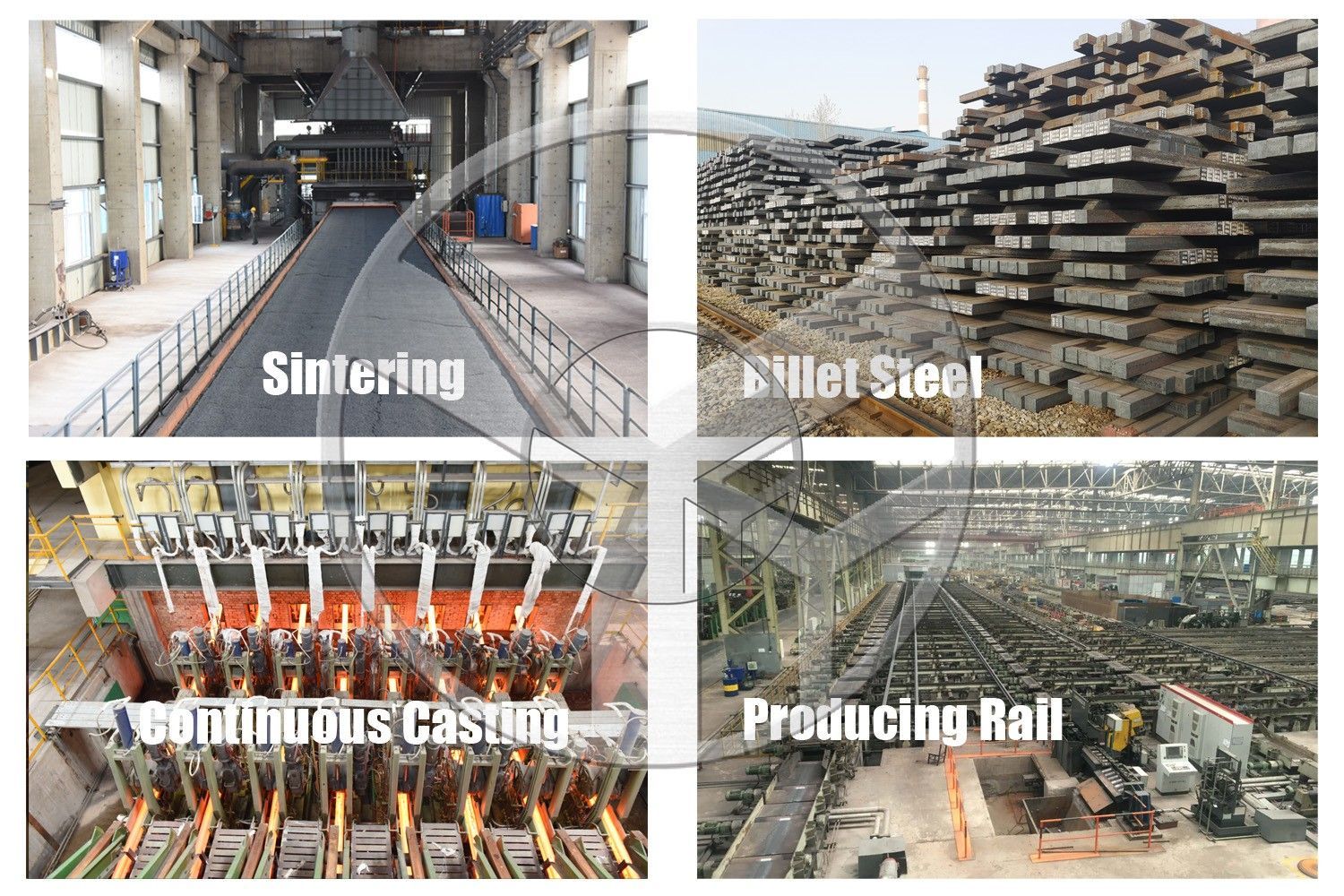

The technical support provided by YYRail can ensure that every rail we deliver provides optimum performance throughout its service life. We supply rail processing, like 45 degree mitre cut, welding process, milling process, special profile processing, etc. Our engineer help customer to design railroad line according to requirements, and build mining railroad line and crane moving line.

Related Products:

Additional reading:What are the advantages of finned tube?

How to Control the Quality of Micro Silica Fume?

What is the galvanized steel coil used for?

What is the process of Hot-dipped Galvanized Steel Coils?

Applications of High-Purity Metal Chromium

Galvanized Steel Coil vs. Galvalume Steel Coil: Which Should You Choose?

Which is better galvanized or Galvalume?