The Advantage of Using Polyethylene for Plastic Parts

The Advantage of Using Polyethylene for Plastic Parts

Polyethylene is the most widely used plastic in the world'and with good reason. Because of its superior impact strength and ability to stretch thin without breaking, it has uses in almost every industry. The advantage of using polyethylene for plastic parts comes down to one thing: versatility.

For more information, please visit our website.

History

The discovery of polyethylene as it exists today took place in the s in the United Kingdom, and it was actually an accident that resulted in a semi-crystalline material. It went into production in , on the same day Germany invaded Poland. Polyethylene quickly found its use as insulation for radar equipment, which gave England a much-needed competitive edge.

Uses

Today, more than 100 million tons of the material's resins are produced every year, adding up to 34 percent of the plastics market. Manufacturers can even spin polyethylene thin enough to become a fiber or modify it to be as elastic as rubber. Just a few of the everyday items made of polyethylene include:

- Food wrap

- Shopping bags

- Toys

- Shampoo bottles

- Pipes

- Vehicle fuel tanks

- Protective helmets

- Faux-wood planks

- Machine parts

- Six-ring drink holders

- Computer hardware casings

- Playground equipment

- Laundry bags

Grades

Low-Density

LDPE is an extruded material that offers low moisture permeability. This grade is most appropriate when good corrosion resistance is necessary, but other qualities are optional'qualities such as stiffness, high temperatures, and structural strength. Its melting point is between 105 and 115 degrees Celsius. LDPE is flexible and extremely mobile without stress fatigue, making it ideal for orthopedic products, consumer packaging, bags, bottles, and liners.

High-Density

HDPE is the most popular form of polyethylene because it's lightweight with low moisture absorption. Its impact resistance is excellent, as is its tensile strength. Non-toxic and non-staining, HDPE meets FDA and USDA standards for use in food processing. Its melting point is between 120 and 180 degrees Celsius.

Ultra-High Molecular Weight

UHMW PE is most common in parts of machinery and equipment with a lot of wear. It's a good lining in material-handling systems and storage containers. Like HDPE, it meets standards for use in food and pharmaceutical equipment. UHMW PE is lightweight'just one-eighth the weight of mild steel. It's strong, self-lubricating, shatter resistant, abrasion and corrosion resistant, and long wearing. It's as easy to machine as wood.

More Advantages

- Durability even with exposure to the elements

- Good electric insulation

- Recyclable into other products

- Excellent chemical resistance to organic solvents, degreasing agents, and electrolytic attack

- High compressive strength

- Excellent dielectric properties

- Resists most alkalis and acids

- Resists stress cracking

- Retains stiffness and flexibility

Miller Plastics has been in plastic product manufacturing for decades'in fact, we helped develop some of the early plastic-working tools and machines in the '80s. We've learned firsthand the advantage of using polyethylene for plastic parts and can tell you if it's the right material for your project. Contact us or visit our state-of-the-art facilities in Burgettstown, Pennsylvania, near Pittsburgh.

Common Uses and Applications of Polyethylene Packaging

In the expansive world of packaging, polyethylene is a superstar material, celebrated for its myriad applications across countless sectors. Known for its versatility, resilience, and cost-effectiveness, it's a preferred choice in various industries, playing a critical role in our daily routines and the broader economy. This article explores the common uses and applications of polyethylene packaging, emphasizing its essential function in our contemporary lives and industrial activities.

What Is Polyethylene Packaging?Polyethylene packaging is everywhere, from your household items to the products you receive from online shopping. Understanding its nature, types, and history helps consumers and manufacturers alike to appreciate its value and vast potential.

Polyethylene, a thermoplastic resin born from the polymerization of ethylene gas, is appreciated for its lightweight nature, resistance to chemicals, and robustness. It comes in several varieties, including low-density polyethylene (LDPE), high-density polyethylene (HDPE), and linear low-density polyethylene (LLDPE), each with its own set of attributes and advantages.

Common Applications of Polyethylene Packaging MaterialsThe sectors relying on polyethylene packaging are diverse, ranging from food and health to electronics and agriculture. Its universal presence is a testament to its functionality, efficiency, and adaptability in meeting various industrial requirements.

Food and Beverage IndustryPolyethylene food packaging is a common sight in the food and beverage industry. It safeguards everything from fresh fruits to frozen items and liquids, thanks to its exceptional ability to resist moisture and preserve freshness. For example, HDPE is the material of choice for milk containers, while LDPE is favored for its flexibility in products like squeezable bottles and film wraps.

Medical and Pharmaceutical SectorIf you are looking for more details, kindly visit SUNUA.

Additional reading:What Are Marine Hoses Made Of?

Why is Industrial Filter Fabric Better?

Are Rubber Stoppers Truly Chemical-Resistant?

What are the benefits of PVC-free Laminating Film?

What Are the Different Types of Hydraulic Hoses

Floating Dock Pipe | ISCO

Key Questions to Ask When Ordering dredge floats

The medical sector depends heavily on the hygienic and protective nature of polyethylene product packaging. Its resistance to contamination and precise engineering capabilities make it perfect for items such as medicinal containers, syringes, and sterile wraps for medical instruments. Its adaptability and strength are especially important for child-resistant and tamper-evident pharmaceutical packaging.

Consumer Goods and ElectronicsIn the realm of consumer goods, polyethylene packaging solutions provide a lightweight, sturdy, and economical method to safeguard products during transportation. Electronics benefit particularly from anti-static polyethylene bags that prevent static electricity, protecting sensitive components from electrostatic discharge during movement or storage.

Agricultural ApplicationsIn agriculture, the usefulness of polyethylene extends beyond product packaging to structural applications. High-strength polyethylene films are crucial in greenhouses, creating a controlled cultivation environment by managing temperature, humidity, and light. Furthermore, UV-resistant polyethylene packaging is essential for storing and shipping agricultural products, providing protection from sunlight and decay.

Environmental Impact and SustainabilityAs the conversation around environmental conservation gains momentum, the recyclability and sustainable alternatives of polyethylene packaging come under scrutiny. The industry's response through innovative measures is shaping the future of packaging, making it more eco-friendly and sustainable.

Recyclability of Polyethylene MaterialsOne significant benefit of polyethylene packaging is its recyclability. Both HDPE and LDPE materials are commonly recognized in recycling programs, positioning them as more eco-friendly alternatives to many other plastics. Recycled polyethylene can be reformed into new packaging, minimizing waste and reliance on virgin materials.

The Drive for Bio-based PolyethyleneAmid escalating environmental concerns, there's a surge in interest for bio-based polyethylene, derived from renewable sources like sugarcane, as a substitute for conventional petroleum-based polyethylene. This transition reduces the carbon footprint and offers a sustainable packaging option without sacrificing the advantageous properties of the material.

ConclusionThe common uses and applications of polyethylene packaging highlight its undeniable presence and critical role in modern society. Its integration into various aspects of our lives speaks volumes about its utility, necessity, and the continuous innovations aimed at making it more sustainable and environmentally friendly.

For more insights or inquiries on polyethylene packaging solutions, please feel free to contact MDI today. Our team is ready to assist you with expert advice and information.

If you want to learn more, please visit our website polyethylene material exporter.

Are Black HDPE Double Wall Corrugated Pipes Eco-Friendly?

How to Choose Sinco Products: A Comprehensive Guide

The Efficiency and Environmental Benefits of Plastic Crusher Machines

Polypropylene Sheet: A Versatile and Sustainable Solution for Diverse Applications

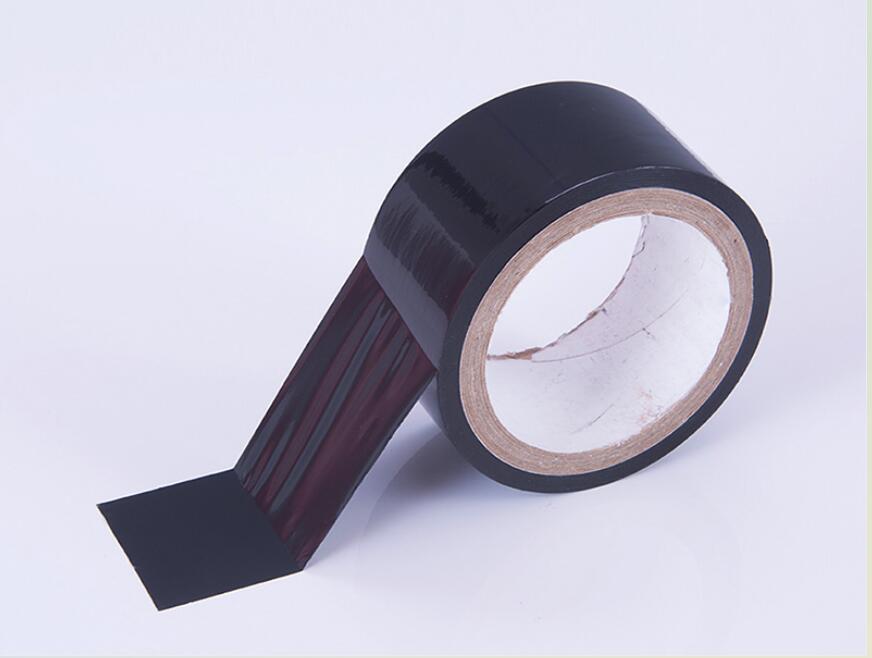

Benefits of using PE surface protection film

What industries utilize custom seal and rubber products?

RPET Fabric: What You Need to Know