How Does Ultra High Power Graphite Electrodes Work?

Zhongsheng supply professional and honest service.

When it comes to industrial applications that require high levels of electricity and heat, ultra-high-power graphite electrodes play a crucial role. These specialized tools are designed to withstand extreme temperatures and provide the necessary conductivity for a variety of processes such as steel production, metal smelting, and even electric arc furnaces.

But how exactly do ultra-high-power graphite electrodes work, and what makes them so effective in these demanding applications? Let's delve into the science behind these innovative tools and explore their unique capabilities.

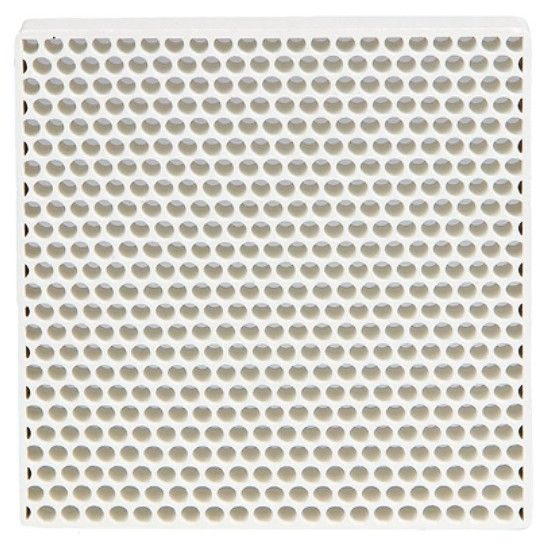

Graphite electrodes are made from a form of carbon that is engineered to have high levels of purity and thermal conductivity. This allows them to withstand the intense heat generated in industrial processes and also ensures that they can efficiently conduct electrical currents. .

In the case of ultra-high-power graphite electrodes, these properties are further enhanced to enable them to handle even higher levels of electricity and heat. This is achieved through a combination of advanced manufacturing techniques and specialized materials that are carefully selected to maximize performance.

One of the key features of ultra-high-power graphite electrodes is their low electrical resistivity, which allows them to efficiently carry large currents without overheating. This is essential in applications where high levels of electricity are needed, such as in the production of steel or other metals.

Additionally, ultra-high-power graphite electrodes are designed to be highly resistant to thermal shock, which is a common issue in processes that involve rapid changes in temperature. By withstanding these fluctuations, these electrodes can maintain their structural integrity and performance over extended periods of use.

Another important aspect of how ultra-high-power graphite electrodes work is their ability to form a stable arc with the material being processed. This is crucial in applications such as electric arc furnaces, where the electrode must maintain a consistent and controlled arc to facilitate the melting of metals or other materials.

Additional reading:Development prospect of industrial graphite products

What are the advantages of finned tube?

How to Control the Quality of Micro Silica Fume?

What is the galvanized steel coil used for?

What is the process of Hot-dipped Galvanized Steel Coils?

Applications of High-Purity Metal Chromium

Galvanized Steel Coil vs. Galvalume Steel Coil: Which Should You Choose?

To achieve this, ultra-high-power graphite electrodes are carefully machined and shaped to ensure a precise and uniform contact with the material being processed. This results in a stable and efficient arc that maximizes energy transfer and minimizes waste.

In addition to their high conductivity and thermal properties, ultra-high-power graphite electrodes are also known for their durability and longevity. Unlike other types of electrodes that may degrade quickly under high heat and electrical loads, these specialized tools are designed to last for extended periods without compromising their performance.

This is achieved through a combination of high-quality materials and precise manufacturing techniques that result in electrodes with exceptional strength and resistance to wear. As a result, ultra-high-power graphite electrodes are able to withstand the harsh conditions of industrial processes and provide reliable performance over the long term.

In conclusion, ultra-high-power graphite electrodes are a critical component in a variety of industrial applications that require high levels of electricity and heat. Through their unique combination of conductivity, thermal resistance, and durability, these specialized tools play a crucial role in processes such as steel production, metal smelting, and electric arc furnaces.

By understanding how ultra-high-power graphite electrodes work and the specific features that make them so effective, industries can optimize their operations and achieve superior results. With their unmatched performance and reliability, ultra-high-power graphite electrodes are truly the backbone of modern industrial processes.

For more information, please visit our website.

For more information, please visit Regular Power Graphite Electrodes.

Additional reading:Which is better galvanized or Galvalume?

Which is better cone filter vs basket filter?

What Are Common Wire Nails Used For?

What is extrusion screen pack?

How Much Silica Fume Can Be Used in Concrete?

What is Aluminum Casting Flux?

10 Frequently Asked Questions About PC Wire