Exploring the Versatility and Precision of Fiber Laser Marking Machines

In the world of modern manufacturing and industrial processes, the demand for precision, speed, and versatility has led to the rise of innovative technologies. Among these, the fiber laser marking machine stands out as a transformative tool that has revolutionized the art of marking and engraving across various industries. This article delves into the capabilities, advantages, and diverse applications of fiber laser marking machines.

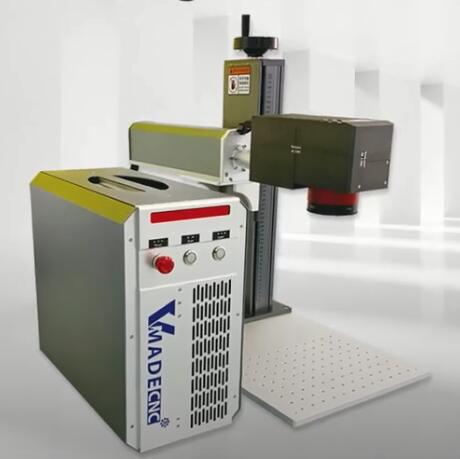

Unveiling Fiber Laser Marking Machines

Fiber laser marking machines are cutting-edge devices that utilize fiber laser technology to create permanent marks, engravings, or patterns on a wide range of materials. Unlike traditional marking methods that rely on mechanical tools or chemical etching, fiber laser marking machines employ a high-energy laser beam to create precise and intricate markings. The technology's exceptional precision, non-contact process, and minimal heat-affected zone make it suitable for an array of applications.

Precision Beyond Measure

The hallmark of Desktop fiber laser marking machines is their unparalleled precision. These machines can create intricate and detailed markings with remarkable accuracy, down to the micron level. This precision opens doors for industries that require intricate designs, small fonts, barcodes, and data matrix codes to be etched onto their products. From medical devices and electronics to jewelry and automotive parts, fiber laser marking can elevate the aesthetic appeal and functionality of a diverse range of products.

Diverse Material Compatibility

One of the standout features of fiber laser marking machines is their versatility in marking various materials. Metals like stainless steel, aluminum, titanium, and brass can be marked with exceptional clarity and permanence. Additionally, plastics, ceramics, glass, and even certain organic materials can be marked, providing an avenue for creativity and innovation across industries. This adaptability streamlines production processes by accommodating a wide array of materials within a single machine.

Speed and Efficiency

Fiber laser marking machines are renowned for their speed and efficiency. The concentrated laser beam can execute marks swiftly, enabling high-volume production without compromising on quality. This efficiency is particularly advantageous for industries that demand quick turnarounds, such as electronics manufacturing, where intricate part identification is essential.

Non-Contact and Non-Destructive

The non-contact nature of fiber laser marking ensures that the material being marked remains unaltered. This non-destructive quality is especially valuable for delicate materials that could be damaged by traditional engraving methods. Additionally, fiber lasers create minimal heat-affected zones, reducing the risk of warping or distortion, which is crucial for precision components.

Eco-Friendly Solution

Fiber laser marking is an environmentally friendly marking solution. Unlike chemical etching or ink printing, it does not involve the use of consumables, solvents, or inks. This not only reduces waste but also aligns with sustainability efforts within industries striving for eco-conscious practices.

Wide Range of Applications

The applications of fiber laser marking machines span across numerous industries. In aerospace and automotive sectors, they are used for part identification, traceability, and anti-counterfeiting measures. In the medical field, they enable permanent and safe marking on surgical instruments and implants. Jewelry makers rely on fiber lasers for engraving intricate designs on precious metals, while electronics manufacturers use them for labeling circuit boards and components.

Conclusion

The advent of fiber laser marking machines has transformed the way industries mark and engrave materials. With their unmatched precision, compatibility with various materials, efficiency, and non-contact process, these machines have become an indispensable tool for manufacturers across the globe. Whether enhancing product aesthetics, improving traceability, or advancing anti-counterfeiting efforts, Vmade fiber laser marking machines continue to redefine the possibilities of modern marking technology. As these machines evolve and become more accessible, the impact on industries is bound to grow, further solidifying their role as a game-changing innovation.