Advantages of Color Coated Steel Coils

I. Introduction

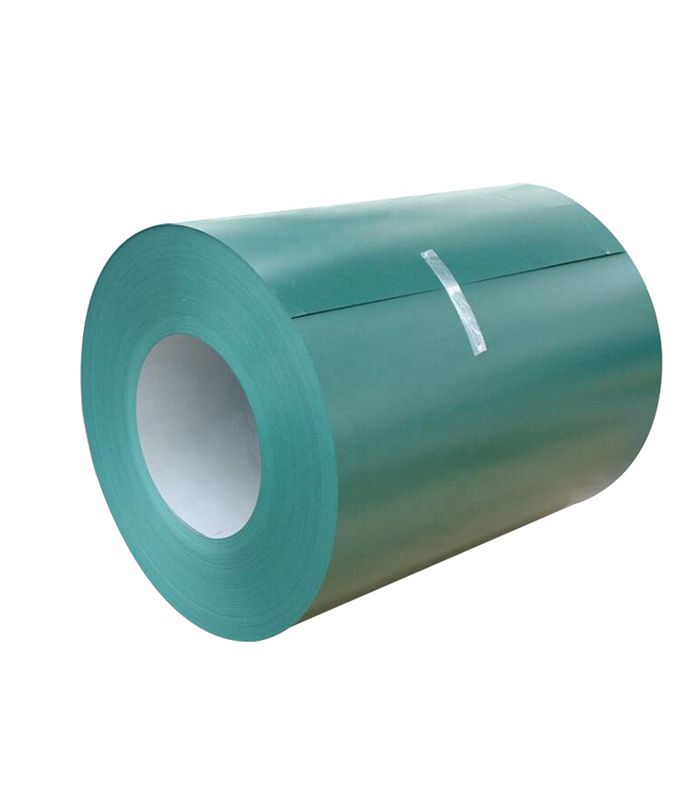

Color coated steel coils, also known as pre-painted steel coils, are steel sheets or strips coated with a layer of paint and primer. This coating enhances their visual appeal and provides an additional layer of protection against corrosion and weathering. The color coated steel coils find wide-ranging applications in industries such as construction, automotive, appliances, and more.

II. Advantages of Color Coated Steel Coils

A. Enhanced aesthetics

One of the significant advantages of color coated steel coils is their ability to enhance the aesthetics of various structures. With a wide range of vibrant colors and finishes available, architects and designers have the freedom to create visually appealing buildings, roofing, and other applications. The color options and high-quality coating ensure a long-lasting attractive appearance.

B. Corrosion resistance

Color coated steel coils are designed to provide excellent protection against corrosion. The combination of a metallic substrate and the paint coating acts as a barrier, preventing the steel from coming into direct contact with environmental elements that cause corrosion, such as moisture and oxygen. This corrosion resistance extends the lifespan of the coated steel, reducing maintenance costs.

C. Durability and longevity

The manufacturing process of color coated steel coils involves applying multiple layers of coating, including a primer and a top coat. These layers contribute to the durability and longevity of the material. The coils can withstand harsh weather conditions, UV radiation, and mechanical stress, ensuring their performance and appearance remain intact over time.

D. Versatility in design

Color coated steel coils offer designers and architects immense flexibility in terms of design options. The wide range of colors, finishes, and patterns available allows for the creation of visually striking structures and products. Whether it's a modern, sleek look or a traditional aesthetic, color coated steel coils can be customized to meet the desired design requirements.

E. Energy efficiency

Color coated steel coils can contribute to energy efficiency in buildings. The reflective properties of certain coatings can help reduce heat absorption, leading to lower energy consumption for cooling purposes. This energy-saving characteristic makes color coated steel coils an environmentally friendly choice while also providing cost savings in the long run.

III. Manufacturing Process of Color Coated Steel Coils

The manufacturing process of color coated steel coils involves several stages that ensure the production of high-quality, durable products.

A. Pre-treatment

Before the coating process begins, the steel substrate undergoes pre-treatment. This step involves cleaning the surface to remove impurities, such as rust, oil, and dirt. Pre-treatment prepares the steel for optimal adhesion of the subsequent layers.

B. Primer coating

Once the surface is clean, a primer coating is applied to enhance the adhesion of the subsequent layers. The primer acts as a protective layer and promotes better bonding between the steel and the top coat.

C. Top coating

After the primer, the top coating, which contains the desired color pigment, is applied. The top coat provides the aesthetic appeal and additional protection against environmental factors.

D. Curing and cooling

Once the top coat is applied, the coated steel passes through a curing oven. The heat in the oven allows the coatings to chemically bond with the substrate, ensuring durability and adhesion. After curing, the steel undergoes a cooling process before it is ready for further processing or application.

IV. Popular Applications of Color Coated Steel Coils

Color coated steel coils find extensive use in various industries due to their versatility and aesthetic appeal. Some popular applications include:

A. Construction and architecture

Color coated steel coils are widely used in the construction industry for roofing, wall cladding, and structural components. The ability to achieve diverse designs and colors makes them a preferred choice for both commercial and residential buildings.

B. Automotive industry

In the automotive industry, color coated steel coils are utilized for the manufacturing of car bodies, doors, and other exterior parts. The corrosion resistance, durability, and design options make them suitable for enhancing the visual appeal of vehicles.

C. Appliances and electronics

Color coated steel coils are used in the production of household appliances such as refrigerators, washing machines, and air conditioners. The vibrant colors and protective coating ensure that these appliances not only perform well but also add aesthetic value to homes.

D. Packaging industry

The packaging industry benefits from color coated steel coils for the production of attractive and durable packaging materials. These coils are used in manufacturing containers, cans, and other packaging products, providing a visually appealing and protective solution.